Parts of a Turbo

This site contains affiliate links to products. We may receive a commission for purchases made through these links.

>>> Get The BEST PRICES on NEW and USED Turbochargers on eBay <<<

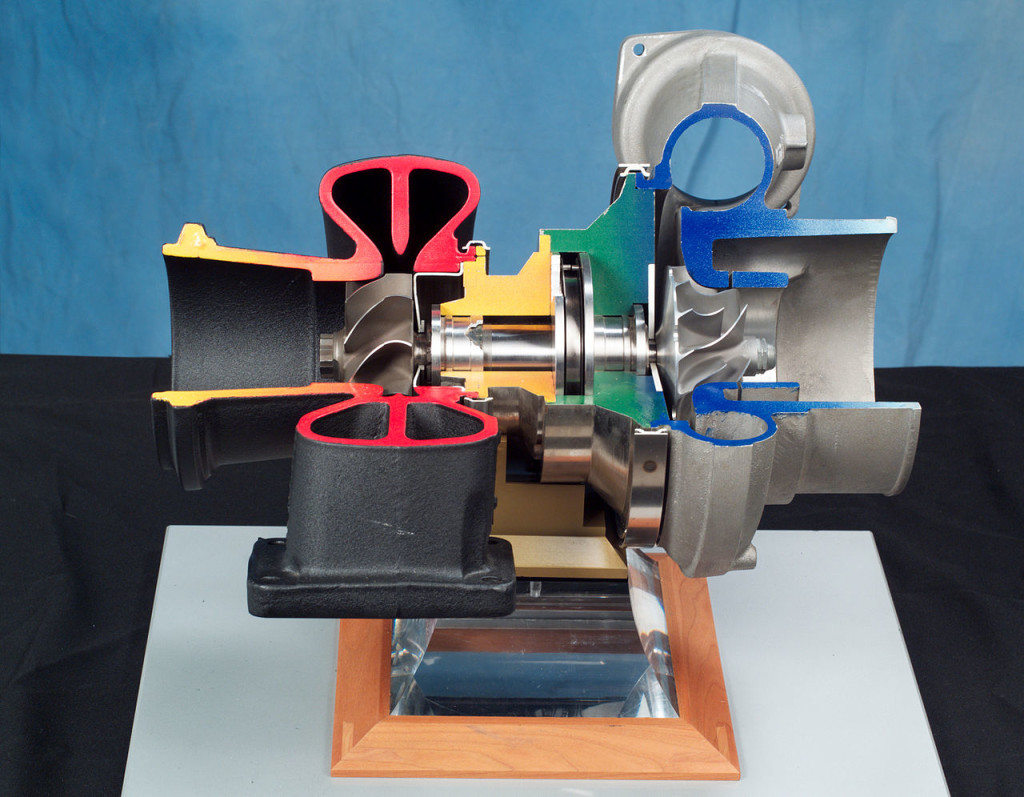

When you’re looking at a turbocharger from the outside, it doesn’t really seem like very much more than a big metal box with a couple of fans in it. But in reality, turbos are much more complex than that – and there are numerous different parts of a turbo that all work together to generate as much boost as possible to power your engine.

While one short article can’t possibly go into full detail about all of the different parts of the countless available turbochargers for sale, but we can at least go over some of the most common parts and the role they play in improving your vehicle’s performance.

Turbine Wheel

One of the core parts of a turbo regardless of the model or manufacturer, the turbine wheel is the piece which is responsible for taking an engine’s exhaust and converting it into energy. In practice, the turbine wheel is located in the turbine housing and should be connected to the engine’s exhaust manifold.

Compressor Wheel

Similar to the turbine wheel, the compressor wheel is situated within the compressor housing and is one of the core components of all turbochargers. As the turbine wheel rotates and powers the compressor wheel, pressure is created within the engine’s intake, allowing more air to be funneled into the cylinders.

Wastegate

As an engine works harder, a greater amount of exhaust is produced. This, in turn, causes the turbine to spin faster, forcing even more compressed air into the intake. Eventually this would cause the engine to perform beyond its safe operating range and overheat, potentially even melting in some extreme cases. To prevent this, turbochargers are installed with a wastegate which allows excess exhaust to be vented out before reaching the turbine.

Charge Air Cooler

When you compress air, just like a turbo’s compressor wheel does, you’re also creating heat. To combat pumping extremely hot air into already hot engines, many turbos are equipped with a charge air cooler – also referred to as an intercooler – which works just like a radiator to cool down the inducted air that passes through it.

Center Housing and Rotating Assembly

Without argument, the parts of a turbo which take the most abuse are often the center housing and rotating assembly. That’s because these are the parts which connect the turbine wheel and compressor wheel, and as a result see some of the most wear and highest temperatures among all of a turbocharger’s parts.

Fluid & Ball Bearings

Fluid bearings act to protect the rotating shaft from damage while it’s rotating up to 150,000 times a second. Traditional metal ball bearings would quickly overheat under that sort of stress, so turbochargers typically use a fluid bearing system which reduces friction and helps maintain a healthy temperature. Some high-end turbos even use special composite ball bearings which are designed to perform even better than fluid, with less friction and a greater dissipation of heat.

Putting It All Together

If this all sounds like a lot to take in, don’t worry – you don’t need to be an expert mechanic to install a turbocharger. While there positively are many different parts that make up a turbo, most are secured within the housing and even the average auto performance tuner will rarely – if ever – have to deal with them.

When you’re ready to learn some more about how the parts of a turbo work together, make sure to check out our simple-yet-comprehensive article, ‘How Does a Turbo Work?’, or spend some time browsing through our continuously growing collection of turbocharger reviews.

>>> Get The BEST PRICES on NEW and USED Turbochargers on eBay <<<